11 Parts Of Car Starter Motor And Function

Starter motor components – engine starting system is a

system that have a function to crank the engine for the first time. The working

principle of starter motor is to rotate the engine crankshaft via flywheel

using electric motor circuit. The result is a rotating crank and engine cycle

can be triggered to work continuously.

In this article, we will learn all about parts of starter

motor and their function. Check the article below.

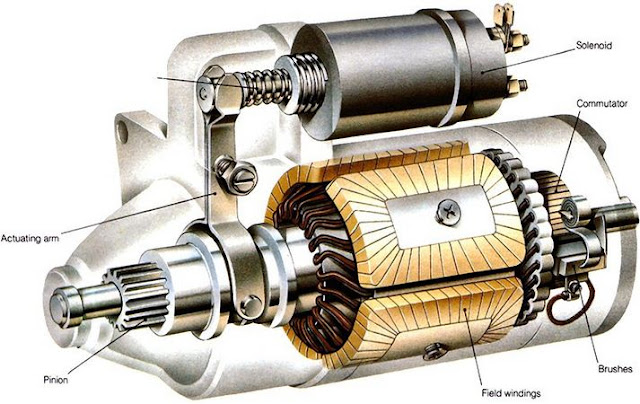

All Parts Of Starter Motor and function

img by jcrsupplies.co.uk

1. Solenoid starter

The first component you can see on the part that looks like

a small tubular part on the main motor. This component is named solenoid

starter because it contains two solenoid. The main function of Solenoid starter

is to push the pinnion drive gear and give voltage on main motor.

There are two solenoid in this component namely;

- Pull in coil, this component works to push the plunger to push the drive pinion gear.

- Hold in coil, is a similar component located in front of the pull in coil. Its function is to withstand the movement of the pull in coil and connect the battery current to the main motor.

The shape of the solenoid is like a coil, where an iron core

is placed in the middle of a copper coil. But this winding has a large number

and the dimensions are also larger so as to move the plunger with a strong and

fast.

2. Solenoid plunger

The plunger is located at the end of the pull in coil. Its

function is only one that connects the movement of pull in coil to drive lever.

In other words, this component only acts as a connecting rod. However, this

plunger material is also strong because it will connect the pull in coil pull

that have strong movement.

3. Solenoid cap

The solenoid lid is a starter solenoid cover circuit located

on the front of the starter. Not only as a cover, but this part is also used as

a media liaison between the current from the system to the starter actuator.

Actually there are 3 pieces of terminal on the starter motor ie

- Terminal 50, is a terminal connected to the starter circuit of the ignition key. Through this terminal the starter motor gets the command to active or not. When terminal 50 gets current then the solenoid will work and the starter will react.

- Terminal 30, the terminal which directly gets the electric current from the battery. In other words electric current is always available at this terminal when the motor is off or on.

- Terminal C, the terminal used to channel the main currents from the solenoid to the starter motor in order to rotate. It will connect the current from terminal 30 when terminal 50 gets current.

4. Field Coil

We go to inside the motor starter, here there are many

components that you can find. First you can find the field coil. What is a

field coil? field coil is a series of magnetic coils used to generate magnetism

around the coil rotor. According to the working principle of an electric motor

that requires a magnetic field around the rotor, this component will provide

it.

But the coil field is not a permanent magnet, the field coil

will only generate a magnet if there is a current input from terminal 50. This

process we usually call the process of electromagnetic induction. The field

coil is also consists of several parts such as

Yoke, is the housing where the coil is located. In this case

the coil lies inside the yoke.

Pole core, is a flat iron core which is used as a place of

welding of copper to become a coil.

This coil is made of ordinary copper coils make with a

certain direction around the pole core, in the yoke there are about 4 to 6

units of pole cores are interconnected to obtain great magnetism.

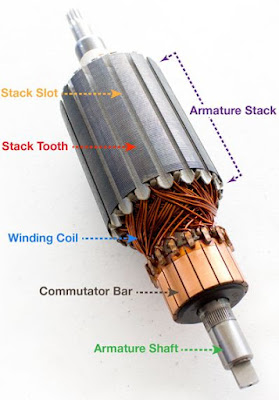

5. Armature coil

The next component, inside of starter motor, it is commonly

referred to as a coil rotor or coil located around the motor shaft. The main

function of the armature coil is also as a magnetic field generator that will

be reacted with magnet field coil for the occurrence of movement.

The shape of armature coil such as rotor that hav tubular

shape. In general it is coated by copper, the difference with field coil, can

be find in its dimmension and amount of coopers. Armature coil has a large

number of windings and the amount of coopers also quite large, so the diameter

of the coil is also larger.

6. Commutators

img by groschoop.com

The next component, located on the front of the armature

coil, it shaped like a segmented copper plate. The function of the commutator

is to connect the electrical current from the brush to the armature coil. The

segmented form of commutator prevents short circuiting of electric current

because in the process the commutator will be connected to positive and

negative currents directly.

7. Drive lever / Actuator shaft

We go back into the solenoid, here there is a fork-shaped

component that serves to move the pinion gear. The drive lever works with the

principle of the lever, which will bring up the pinion gear when the other end

is pushed in opposite directions. Who is pushing? this is a function of pull in

coil through plunger. While the other end will make the pinion gear pushed out and

connected with flywheel.

8. Brushes

The next component lies on the main motor. Here is a series

of brushes used to connect the electrical current from a static conductor to a

dynamic conductor. That is, this brush will send an electric current from

terminal 50 to the armature coil that moves around through the commutator.

In a starter motor, there are usually about 4 or more

brushes with two as a positive brush and the other two as negative brushes. The

material of this brush is also made of copper but softer, to keep the

commutator from wearing out. But, the impact brush become more quickly wear

out. If this happens then the starter will be difficult to run.

9. Drive Pinnion Clutch

The next component, we will encounter a mechanical clutch

that has function to connecting and disconnecting rotation from the starter

shaft to the flywheel. Why the rotation need to be disconnected? it is because

the stater motor is unlikely to keep working when the engine is running. So in

a normal condition, the starter will be connected and when the starter system

is turned on the round starter will be connected with flywheel.

How to work this clutch that is by utilizing slide gear with

tilt model. this is because there is an overlap clutch component located at the

end of the pinion drive. When the starter system is turned on then the drive

lever will push this clutch, but with the angled slide gear then the pinion

drive will move out while rotating beyond the starter spin.

This is intended for pinion to be fast and perfect timming

connection with a flywheel gear. In the reduction strater type, this coupling

component gets an additional part that is used as a rotary reducing gear, the

goal is that moment on pinnion gear becomes bigger.

10. Drive pinnion gear

The next component is shaped like a gear in general that is

located at the end of the drive pinion shaft. The function of this pinnion gear

is to connect the rotation of the generated electric motor to the engine

crankshaft via flywheel. The pinnion diameter is quite small compared to the

flywheel so it will increase the gear ratio that makes the starter system

capable to rotate high capacity engine.

11. Motor housing

The last part is housing, which has the function as a

protective part and as a place to put various components of starter. This

housing is made of metal consisting of tubular main housing, pinion housing as

pinion gear and stamped in front of the main housing as a starter chassis

cover.

Thus the full article and clear about the parts of the

starter motor and their functions on cars and motorcycles. Hope can increase

our insight and benefit us all.